See what the "burning rate" in other dictionaries. The burning rate of certain types of combustible materials

SOLID FUEL BURNING RATE

Linear burning rate of solid fuel - the speed of movement of the burning surface into the depth of the charge - depends on the composition and technology of the charge, the temperature of the charge T 3,chamber pressure r,gas flow velocity along the burning surface v, stretching the fuel, accelerating a = ng,directed to the burning surface, as well as from other factors:

and = u (T 3) f (p) fi (v) f 2 () f 3 (a).

The functions included in this dependence are assumed to be independent and determined experimentally.

1. The dependence of the burning rate on temperature is expressed in one of the following forms:

but) ![]() ;

;

b) ![]() ;

;

at) ![]() .

.

Constant D 1 / V = (1 ... 5) 10 3 1 / ° С, with larger values refer to ballistic, and smaller values - to composite solid fuels; accepted T n = =20 ° C.

2. The dependence of the burning rate on pressure is usually expressed in

one of the following forms:

but) u = u;

b) u = a + bp;

at) u = or u =

As a rule, the power dependence is used in the internal ballistics of solid propellant rocket motors. and= u x p v,where v= 0.2 ... 0.8, with large vbelong to ballistic, and smaller - to mixed solid fuels. For some fuels in a limited pressure range v= 0, there may also be sections where v< 0.

3. The burning rate depends on the gas flow rate along

burning surface starting with the "threshold" value of the flow rate

v n or other determining parameter. The forms of dependence are different,

namely:

a) f(v) = l + k v (v-v) with v v,

(for JPN fuel, we have v = 180 ... 200 m / s; k =0,0022 s / m) or f = 1 + k (p) with n; where for some ballistic fuels we have

; ![]() (measured in cm / s p - 10 MPa);

(measured in cm / s p - 10 MPa);

b) f(v) = l + k v as v v,

where for ballistic fuel H we have

; v 140 ... 200m / s;

for example, P 0.4; to0,8;

d) at ![]() ,

,

where for ballistic fuels we have (S / f)100; k0,003...0,004; S -area of burning surface in cross section with coordinate x:

1 at ![]()

d) 0,0125 ![]() at

at

where for ballistic fuel H we have (FW, 1971, №l) = 0.04;

J =1,6; J n = 5.6.

Coefficients k v, k, k, kand kthey are not physical constants of fuel, but within the limited limits of a specific intraballistic calculation, they are assumed to be constant. Fuels with low burning rates are more susceptible to erosive burning than fuels with high speeds. Near v n when v< v n наблюдается уменьшение скорости горения (отрицательная эрозия, см. п.2.3.2).

4. The dependence of the burning rate on tensile strain has

view f 2 () = 1 + b;value b- about one.

5. Combustion rate of solid fuel increases with increase in usko

rhenium ng,acting perpendicular to the burning surface; So,

for gunpowder N we have (according to B.I. Goncharenko) that f 3 (n) =

equals 1; 1.2; 1.4; 1.5 and 1.6 when p= 0.7 10 3; 1 10 3; 4 10 3; 8 10 3 and 18 10 3 respectively.

For metallized composite solid fuels, in which the mass fraction of aluminum is z A 1, the relationship between f 3 = and phas the form (FW, 1978, № 6):

![]() ,

,

where the pressure is measured at 10 Pa, the burning rate is in mm / s.

At very high accelerations (at the saturation point) for various fuels f 3 () = 1,5 ...2,5 .

Increase andunder the action of acceleration depends on the size of the aluminum particles contained in the composite solid fuel. When the acceleration vector deviates from the normal to the surface, the effect pon andfirst decreases approximately as the cosine of the angle of inclination, and at angles 0 ... 70 0, the acceleration does not affect the burning rate.

The burning rate of the metal-free composition of the purified components does not change with an increase in overload up to 10 3 g.

6. The burning rate under conditions of rapidly changing pressure differs from the stationary value, and this change can be approximately described, for example, by the dependence

![]() ,

,

where = 0.5 ... 2; but -coefficient of thermal diffusivity of the fuel.

It is possible to interrupt the burning of fuel with a sufficiently rapid pressure drop:

For ballistic fuels;

- u / d - for mixed (d -diameter of grain oxidizer).

The burning rate of various parts of the charge of solid fuel is also influenced by the design features, manufacturing technology and operating modes (storage) of solid propellant rocket motors.

The steady burning of solid fuels is determined by the following sources of heat:

1) total exothermic reactions occurring in a thin surface layer of fuel;

2) total exothermic processes occurring in the smoke and gas mixture.

The fuel is heated to the temperature required for stable combustion, mainly by the first source of thermal energy; however, most of the fuel in the surface layer is dispersed.

When quasi-stationary combustion of solid fuel with a speed of andin the heated layer, the temperature distribution is set, approximately described by an exponential dependence (Fig. 2.1)

T (x) T 3+ (T s -) exp ( -xu / a),

where T s, T 3 -surface temperature of burning fuel and the initial | charge temperature.

For ballistic fuels there is an unambiguous dependence of the surface temperature. T son burning speed and.For fuel H Tequal to 600, 650, 690 and 720 K with and= 0.25; 0.5; 0.75 and 1 cm / s, respectively.

The total amount of heat accumulated in the heated layer

.

.

The main supply of this heat is enclosed in a layer of thickness = a / andwarm-up time which order t 4 = -a / and g(thermal relaxation time for ballistic fuel is 60 and 4 ms at a pressure of 0.4 and 6.0 MPa, respectively). Based on this, it can be approximately assumed that for ignition of the charge and sustainable development of the decomposition reaction, solid fuel, it is necessary to transfer a certain amount of heat to the surface layer. /andand heat the fuel surface to a temperature close to the value for a certain time, equal to approximately a / and 2.At the same time, the pressure in the solid propellant solid fuel must be greater than the value necessary for stable combustion.

|

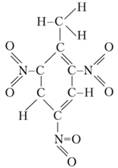

Fig. 2.1 Ballistic fuel combustion scheme:

T 3 -initial charge temperature; - the temperature at the interface of the solid and gas phases; 1 - the initial state of the fuel; 2 - zone of heating and primary decomposition of components; 3 - liquid viscous layer; 4 - gasification zone; 5 - preparation zone for combustible mixture; 6 - burning zone; 7 - products

combustion.

The increase in the burning rate with increasing pressure and temperature of the charge is due to the fact that under these conditions the heating of the surface layer is accelerated. An increase in the burning rate at v\u003e vn is due to an increase in the effective coefficients of thermal conductivity and diffusion in a developed turbulent flow. Under the action of overloads, the agglomerates formed during combustion are pressed to the surface and, being comparable in size with the thickness of the heated layer, increase the local heat transfer to the fuel and lead the combustion front. When a solid fuel is stretched, microcracks appear, which are available for burning, and the linear velocity of the burning surface increases.

Specific parameters of dependence of the burning rate of each charge (or each batch of charges) of solid fuel on pressure and temperature (for example, and = and (T 3) p v)determined by burning a cylindrical sample, booked on the side surface, in a constant pressure device (Fig. 2.2). Determination error and= e / tin this device consists of errors of measurement of several parameters:

|

Fig. 2.2. Constant pressure device for measuring the burning rate of solid fuel:

1 - exhaust valve; 2 - inlet valve; 3 - reducer in the pipeline from the balloon battery; 4-electric ignition coil of solid fuel sample; 5 - sample reserved on the side surface; b - constant pressure bomb; 7 - wires that burn out when passing through the combustion front.

The radiation and the flow of gases in a constant pressure device differ from the radiation and flow of combustion products in an engine. Therefore, the burning rate value measured in a constant pressure device is corrected using an empirical coefficient to and= 1 ... 1.1 for burning conditions in the engine (with v< v n). Коэффициент k v,characterizing the effect of the gas flow rate on the burning rate when v\u003e vn, is determined on special installations (for example, on an installation with GG, similar to that shown in Fig. 5.42, where instead of samples of thermal protective coatings are placed samples of solid fuel) or by burning charges in model solid propellant rocket motors .

The constant pressure device also burns the stretched samples in order to obtain the value . The dependence of the burning rate on acceleration is established when testing model solid propellant rocket motors mounted on a yoke of a centrifugal test bench or when testing rotating rotors around a solid rocket motor.

The addition of metal powders to solid fuels does not have a significant effect on the burning rate (in the absence of large accelerations directed to the burning surface), since the ignition and burning of metals occurs in a gas flow. A distinctive feature of the combustion of mixed metallized solid fuels is that it is a complex sequence of transformations of the original metal (aluminum) particles — agglomeration (coarsening) on the reactive surface of the fuel, their ignition, removal to the gas phase, combustion and movement in it. The oxidizer grains (ammonium perchlorate) are an order of magnitude or more larger than the original aluminum particles contained in the fuel - binder, which fills the pockets between the grains. The intensity of burnout is maximum in the region of the borders with the latter. Therefore, with the passage of a combustion wave, the metal particles accumulated in this pocket merge, and these aggregates are one to two orders of magnitude larger than the original particles. Under certain conditions, aggregates may also merge from neighboring "pockets", and the formation of several aggregates within one "pocket". The subsequent movement and combustion of aluminum aggregates, coagulation and disintegration of A1 / A1 2 O 3 droplets determine the loss of specific impulse, the effect of the multiphase flow of combustion products on the thermal protection of solid propellant rocket motors and slagging. As a result of the analysis of experimental data on the size of aluminum oxide particles in the combustion products, the following formula was obtained:

where d measured vm; t - in with; r - in MPa; d - in microns; t= L/ v; L -engine length

Combustion of solid combustible substances in the initial stage of the occurrence of combustion is called fire. The instability of burning, a relatively low temperature in its zone, the small size of the flame and a small area of the focus are characteristic of such a stat.

The ambient temperature is raised slightly, only directly at the burning hearth.

The initial stage of a fire (ignition) can be eliminated with primary fire extinguishing agents. If the fire is not immediately extinguished, the heat released during combustion, will enhance the process of the latter. At the same time, the size of the flame will increase and the combustion will turn into a stable form. At the same time, the ambient temperature rises and the action of thermal energy emitted by the burning center increases and strengthens the gay effect. And the elimination of such ignition requires a large number of primary fire extinguishing agents, water and foam jets.

With insufficient effectiveness of the fire extinguishing means used or their late use, the combustion continues to develop, its zone increases over a considerable area. At the same time, the temperature increases, a significant amount of thermal energy is released, and convection air flows increase. Under the specified conditions, deformation and collapse of structures are possible.

To eliminate such a fire requires a lot of power and powerful tools.

The burning rate of materials during a fire is different and depends on the burning conditions, the composition of the combustible material and the intensity of heat transfer by the latter from the burning zone.

There are two burning rates: weight and linear. Weight speed is called weight (int, kg ) substances burnt per unit of time (in min h ). The linear rate of burning of solid combustible substances is called the rate of propagation of fire (inm / min ) and the growth rate of the fire area (in m 2 / min ).

The burning rate of solids is variable and depends on the ratio of their surface to volume, on humidity, air access, and other factors.

Based on the data obtained in the study of a number of fires on river vessels, the linear velocity of fire propagation is from 0.05 to 2.5 m / min, and the rate of growth of the area of the fire center is from 0.3 to 50.0 m 2 / min

At the beginning of the fire, about the first 2-3 minutes, there is an intensive increase in the area of its focus on passenger ships to 41-44 m 2 / mission This is explained by the fact that during this period a lot of time is spent collecting personnel for the crew of the vessel and not actively fighting the fire. In the next 10 minutes, when stationary means of youth and foam extinguishing are put into operation, the growth of the area of the fire center slows down to about 6-7 m 2 / min

Research has established that a passenger ship can be destroyed by fire within 20-30 minutes if the organization of its extinguishing is imperfect.

The linear velocity of propagation of fire determines the area of the fire, and the degree of burning out of everything that can burn in this area is the duration of the fire.

The linear velocity of the burning fluid is the height of its layer (in mm, cm), burned out per unit time (in min, h).

The speed of flame propagation during the ignition of combustible gases is from 0.35 to 1.0 m / s.

Burnout rate is called the amount of fuel burning in a unit of time per unit area of combustion. It characterizes the intensity of the combustion fluid in a fire. It is necessary to know it to determine the estimated duration of a fire in tanks, the intensity of heat generation and the temperature regime of a fire, etc.

The burnout rate of a fluid is not constant and depends on its initial temperature, the diameter of the reservoir, the level of the liquid in it, the content of non-combustible liquids in it, the wind speed and other factors.

In tanks with a diameter of 2 m, the rate of burnout of liquids increases with its increase. In practice, it is the same in tanks with a diameter greater than 2 m.

The burnout rate of a liquid spilled on the surface is about the same as in tanks if its thickness is significant.

For example, the burnout rate of oil is 25 cm / h , gasoline -40 cm / h, oil-20 cm / h.

During the fiery burning of petroleum products in the cargo tank is heated fluid.

The heating of the liquid from the upper to the lower layers occurs in the mass of heavy oils at a speed of 30 cm / h, and in the mass of light oils - from 40 to 130 cm / h.

Kerosene and diesel fuel during heating are heated slowly, while not forming a heated layer of the same temperature.

Oil and fuel oil are heated very deeply, the temperature of the layer is almost always above 100 ° C. The temperature of the oil layer can reach 300 ° C and heat the bottom layer of water in the tank.

The temperature of the heated layer of gasoline is usually below 100 ° C, and therefore the bottom layer of water in the tank is not heated.

Warming up the fluid in the tanks can lead to boiling up or release. Under the boiling point refers to the transition in the vapor of a large number of small droplets of water in the oil. At the same time, foam is formed on the surface of the liquid, which can overflow through the side of the tank. Under the release refers to the instantaneous transition of water at the bottom of the tank, in steam. In this case, an overpressure is created, under the action of which the burning liquid is ejected from the reservoir.

The boiling of petroleum products in most cases is due to the presence of water in them and less often a water cushion at the bottom of the tank. All petroleum products containing water are capable of boiling, which during the combustion process is heated above 100 ° C.

Oil and fuel oil can boil only when there is a certain amount of moisture in them: in oil, 3.3% and fuel oil — above 0.6%. "

Boil can lube and heavy gasoline when writing the bottom layer of water.

Cooling the reservoir walls with water jets and periodically introducing a spray of water to one-third or one-fourth of the burning surface prevents boiling and overflowing of heated gasoline or oil from it.

If (the height of the freeboard exceeds the thickness of the heated layer by more than 2 times, then with the introduction of iB, the combustion zone of the sprayed jet of water boils up, but no liquid is transfused from the container.

Dark petroleum products are capable of discharge - oil containing 3.8% moisture, fuel oil containing up to 0.6% moisture.

Ejection of a burning liquid can occur if: water is under the layer; liquid during combustion warms to the depths; the temperature of the heated layer is above the boiling point of water.

The release occurs at the moment when the oil at the water-oil interface is heated above 100 ° C (approximately 150-300 ° C). After the first ejection, a layer of oil heated to a higher temperature comes into contact with water again and a powerful ejection occurs.

Emission in height, range and area of destruction depends on the diameter of the tank. In a tank with a diameter of 1.387 m, the mass of burning oil that is thrown out is from 51 to 145 kg at a height of from 10 to 20 tank heights.

The duration of the ejection process from the tank is from 3 to 60 seconds. The ejection time is different, ranging from 2 to 5 hours and 30 minutes from the start of combustion for various petroleum products with different tanks.

Typically, the release is accompanied by numerous petroleum product takeoffs. The ejection of the entire oil product by one take-off is rare and is observed with a small layer of the remaining oil product and its considerable viscosity.

A characteristic sign of the beginning of the release is the occurrence of vibrations of the walls of the vessel, accompanied by noise and an increase in the size of the flame.

In tanks of larger diameter, the release is faster than in tanks of small diameter. The size of the water cushion layer does not affect the release.

The normal burning rate of a gas and vapor-air mixture is the rate at which the boundary surface moves between the burnt and unburned gases relative to the unburned gas, which is at rest in close proximity to the burning surface.

The works present the experimental values of the propagation rate of combustion for many nonmetallic materials. In the experiments, samples of soft materials (fabrics, rubber, etc.) were used in the form of 200 X 50 mm stripes, the edges of which were embedded in a brass frame, and samples of rigid materials (plexiglas, textolite, polycarbonate, etc.) in the form of rods 200 X 8 X 2 mm. Samples were installed in a 30 m bomb in various positions (from horizontal to vertical). As an ignition source, an electrically heated steel spiral from a wire with a diameter of 0.2-0.3 mm and a length of 30-35 mm was used, which was fixed on the end of the sample. [...]

Values of flame propagation velocity for samples from various materials are given in Table. 5.5. [...]

In all materials studied, the burning rate increases with increasing oxygen pressure. This dependence is different for different materials. For example, when the pressure is increased from 0.2 to 2.0 kgf / cm, the burning rate of the fabric is art. 22376 increases 2.2 times, the skin "Cheprak" - 14 times, and in the tissues art. 3005, stories - 150-250 times. It should be noted that for materials that melt during combustion (nylon and polyester fabrics, plexiglas, polycarbonate), the dependence of the burning rate on pressure is weaker than that of non-melting materials (leather, cotton fabrics, etc.). [...]

The material structure has a significant effect on the burning rate. Materials with a developed surface burn, as a rule, with a higher speed. For example, the burning rate of nylon fabric art. 1516 with a rarefied structure is 3-5 times higher than the burning rate of dense nylon fabrics art. 22376 and art. 22059. Porous materials (foam plastic and OM-12 rubber) have a very high burning rate. [...]

With an oxygen pressure of about 1.0 kgf / cm2, the burning rate of most non-metallic materials is small and is usually several centimeters per second or less. It follows that their use in contact with oxygen is fundamentally permissible in the presence of simple means of detecting and suppressing combustion. However, there are materials whose burning rate reaches 130-150 cm / s. It is clear that the use of such materials in oxygen is practically excluded. [...]

It should be noted that widely used in the manufacture of clothing for work in an atmosphere of oxygen or oxygen-enriched air on the basis of natural; fibers (cotton fabrics) have very high burning rates (up to 150 cm / s). Apparently, this explains that, when the clothing of the service personnel is set on fire in the oxygen atmosphere, it is almost never possible to take quick and effective measures to save people. Fabrics based on synthetic fibers burn in oxygen much slower. Their burning rate usually does not exceed 1-2 cm / s. Therefore, their use in contact with oxygen is preferred (electrification and ignition energy of these tissues will be discussed below). [...]

The intensity of combustion of materials is particularly important to know when considering the possibility of safe use of non-metallic materials, which are usually the most easily flammable and quick-burning structural elements. [...]

The intensity of combustion was determined by the method described in detail earlier (p. 75). [...]

In special experiments, the effect of oxygen pressure (Fig. 5.5) and the size of the sample (Fig. 5.6) on the thermal effect of the combustion of materials was established. The intensity of burning material was calculated as the average of 3-5 experiments. Measurement accuracy at a given pressure of ± 5%. The values of the thermal effect of combustion and the intensity of combustion of some materials at different oxygen pressures are given in Table. 5.7.

Page 1

The burning rate increases with an increase in the degree of unsaturation in the molecule: alkanes, alkenes, alkadienyl-kines. With an increase in the chain length, this effect decreases, but the rate of combustion of air mixtures for n-hexene is approximately 25% higher than for i-heisan.

The burning rate is reduced by the value of Lv - the heat of gasification. It tends to be low for liquids and relatively high for solids. Accordingly, solids tend to burn much more slowly than liquids.

The burning rate depends on temperature and pressure. With increasing temperature or pressure, the burning rate increases greatly. If the combustion reaction proceeds at a very high speed, then a phenomenon occurs that is called an explosion. The explosion can occur from contact with the fire of a heated oil product, the vapors of which are mixed with air. This mixture becomes explosive when it contains a certain amount of fuel.

The burning rate and costs associated with a decrease in flammability depend not only on the type of resin, but also on the presence and amount of fillers, features of the material structure (for example, a multilayer structure using balsa) and on the use of coatings that swell when heated.

The burning rate at constant pressure can be determined by carrying out charge burning in a chamber with a nozzle. If the surface of the charge is constant, then the pressure during combustion almost does not change. In this case, the linear burning rate can be calculated as the ratio of the wall half-thickness (arch thickness) of the powder tube to the burning time. The advantage of the method of determination is the proximity of the burning conditions to the conditions of actual use, the disadvantage is the need to prepare relatively large samples of gunpowder. More simple in laboratory execution and not requiring large quantities of powder is the determination of the burning rate at a constant pressure of a cylindrical armored from the side surface of the charge ignited from the end, with recording the burning time of a section of a certain length or moving the burning zone in time. The first device developed for this purpose by Varg was a glass tube with a diameter of about 30 mm, sealed from below. The tube has two lateral branches in the upper part. One of them connects the tube with a manometer, the other with a large-capacity tank into which gases flow during combustion, due to which almost constant pressure is maintained in the tube. At the top, the tube is closed with a rubber stopper, through which a thin, bottom-sealed glass tube for a thermocouple and a second tube for current conductors, ending with a vos-flame spiral of a thin wire, pass.

The burning rate of hydrazine increases approximately in proportion to the square root of pressure. Above 10 atm, the data is reproduced worse and the average values tend to some constant value that does not depend on pressure. Above a certain pressure, the liquid does not ignite from the heated wire.

The burning rate, as a rule, increases with increasing pressure. This is quite natural in the case when exothermic reactions during combustion take place in the gas phase. Increasing the pressure, increasing the absolute speed of these reactions, brings the zone of their flow closer to the surface of the condensed phase, increases the temperature gradient near this surface and, accordingly, heat transfer to the latter.

The burning rate, if determined in tubes of the same diameter, increases with increasing pressure, not in proportion to it, but more slowly. It is assumed that this is due to heat exchange with the walls of the tube. If the burning rate at each pressure is measured using a tube diameter equal to five times the critical diameter, then the data obtained show (for 97–7% hydrazine) in the pressure range 0–5–1 a direct proportionality of the burning rate to pressure. Comparing the dependence of the burning rate on the burning temperature, which is varied by diluting with inert gases (taking into account the influence of this dilution on the thermal conductivity), we obtain an activation energy of 30 kcal / mol.

The burning rate of a fire, as these experiments have shown, increases with the increase in the fuel load.

The combustion of explosives differs from detonation by the speed of propagation and the nature of chemical transformations. The burning rate is mainly determined by the composition and state of charge. For powders, the burning rate is several hundred /, for solid rocket fuels - from a few mm / s to tens of cm / s. The burning rate of black (smoky) powder is about 300 m / s.

Some explosives can both detonate and burn if a detonation does not occur for some reason or fades. Such a process is often called deflagration, and its speed deflagration speed.

Wikimedia Foundation. 2010

See what is the "burning rate" in other dictionaries:

burning rate - (the speed of the flame front in the fuel air mixture) [A.S. Goldberg. English Russian energy dictionary. 2006] Topics of power engineering in general EN burning velocityrate of combustionburning ratecombustion velocity ...

burning rate - degimo sparta statusas T sritis fizika atitikmenys: angl. burning velocity; speed of combustion vok. Brenngeschwindigkeit, f; Verbrennungsgeschwindigkeit, f rus. burning rate, f; combustion rate, f pranc. vitesse de combustion, f ... Fizikos terminų žodynas

burning rate - 10.2.1 burning rate: The ratio of the length of a burnt part, measured in accordance with the fire resistance test method, to the time required to burn this part, expressed in millimeters per minute. A source … Vocabulary-reference terms of regulatory and technical documentation

burning rate - rus burning rate (g) eng burning velocity, burning rate fra vitesse (f) de combustion deu Verbrennungsgeschwindigkeit (f) spa velocidad (f) de combustión ... Occupational safety and health. Translation into English, French, German, Spanish

MATERIAL COMBUSTION RATE - the linear velocity of propagation of the moving combustion front on the sample material ... Russian encyclopedia on labor protection

burning rate at the actual parameters of the laminar torch - (composition, temperature and pressure) [A.S. Goldberg. English Russian energy dictionary. 2006] Topics of the power industry as a whole EN fundamental burning velocity ... Technical Translator's Guide

weight burning rate of fuel - the rate of burning mass of fuel - [A.S. Goldberg. English Russian energy dictionary. 2006] Topics energy in general Synonyms of the mass burning rate of the fuel EN mass burning rate ... Technical Translator's Guide

linear burning rate - - [A.S. Goldberg. English Russian energy dictionary. 2006] Topics of energy in general EN speed of flame propagation ... Technical Translator's Guide

Reception of indications of counters of hot and cold water supply

Reception of indications of counters of hot and cold water supply Calculation of the area of air ducts of various shapes and fittings

Calculation of the area of air ducts of various shapes and fittings Chemistry of combustion processes. Explosion energy

Chemistry of combustion processes. Explosion energy What will happen if you do not transmit meter readings

What will happen if you do not transmit meter readings