Polymer burning and materials reducing their flammability

Classification of solid combustible materials (TGM)

In accordance with GOST 12.1.044 ?? 89 "Fire and explosion hazard of substances and materials" solid materials are called, the melting or decomposition temperature of which exceeds 50 ° C, as well as substances that do not have a melting temperature (wood, fabrics, etc.).

TGM can be classified according to several criteria:

- chemical composition

- by behavior when heated.

TO hydrocarbons include natural, artificial and synthetic polymeric materials, which include carbon, hydrogen, nitrogen and oxygen. According to the structure of hydrocarbons ?? These materials are homogeneous.

In a separate subgroup include natural organic substances, which are based on cellulose. These include polymeric materials of plant origin (wood, cotton, etc.), which, unlike artificial and synthetic polymers, are not homogeneous materials, but a mixture of natural polymers. Behavior in fire conditions of all plant materials is similar, and for this reason they are united in one group ?? cellulose materials.

Organo-element compounds ?? organic substances, which include elements such as sulfur, phosphorus, silicon, halides and metals. Under fire conditions, organo-organic compounds form particularly toxic substances and for this reason they are distinguished into a special group.

Inorganic solid combustible substances ?? these are metals and non-metals. Almost all metals under normal conditions are oxidized in air. But only those which can ignite in air from an open source of ignition of average power and which burn on their own after it has been removed, are considered to be combustible. Alkali and alkaline earth metals are among the most combustible.

Non-metals include phosphorus, arsenic, silicon, sulfur. The mechanism of their ignition in many ways resembles the characteristics of the burning of metals.

As can be seen from the diagram, all solids can be divided into two classes according to the behavior when heated: gasless and gasifying when heated.

The vast majority of condensed substances belong to the second class. When heated, they gasify, after which a homogeneous combustion of the gasification products takes place. In turn, gasifying TGMs are divided into two large groups according to the way in which they pass into the vapor-gas state. Solid combustible substances that pass into the gaseous state through the liquid phase (melt under elevated temperature conditions) are commonly called TGM of the first kind.

The process of ignition of TGM of the 1st kind repeats the process of preparation and ignition of combustible liquids. Their burning proceeds in a homogeneous mode.

Solid combustible materials that pass into the vapor-gas state bypassing the liquid phase due to sublimation or thermal destruction of molecules are called TGM second kind. When burning substances of this group, both homogeneous and heterogeneous mode of combustion is possible.

General laws of ignition and combustion TGM

The processes of formation and development of combustion for solid combustible materials have much in common with the processes of combustion of gases and liquids that we studied earlier. However, apart from the general features, there are a number of features due to the state of aggregation and differences in structure.

Consider the mechanism of ignition of TGM. When TGM comes into contact with heat from high temperatures, heat exchange occurs, and the following processes occur with the material:

- Heating of the surface layer to the phase transition temperature (melting or thermal decomposition). If this material is of plant origin, then moisture starts to evaporate first.

- Further heating leads to the onset of a phase transition. If it is a TGM of the 1st kind, then melting and transfer of the material into the liquid phase takes place, then the melt is heated to the boiling or decomposition temperature. If this material is the 2nd kind ?? immediately begins the process of sublimation or decomposition with the release of volatile products.

- The formation of a combustible vapor-air mixture and its preheating.

- Self-ignition of the vapor-air mixture followed by combustion.

Thus, if during the combustion of a liquid, the heat flux coming to the surface is consumed only for heating and evaporation of the liquid phase, then for solids, in addition, costs for melting and decomposition are necessary.

At each stage, specific physicochemical processes take place that determine the state of the system. The following zones correspond to these stages:

where t 0, t feast, t h, t mountains ?? the initial temperature, the pyrolysis temperature, the ignition temperature, the combustion temperature, respectively.

- source material zone;

- zone of material preheating to the temperature of physicochemical transformations;

- it is a phase transition in which the material is melted or decomposed;

- the zone of formation of the combustible mixture and its heating to the ignition temperature;

- the zone of the flame front, where most of the heat energy is released and the maximum temperature is observed;

- the zone of combustion products, where the reaction products are mixed with cold air.

Thus, the burning process of most TGMs begins with a homogeneous regime. Combustion is characterized by a high propagation velocity, powerful convective currents and radiation.

The time of ignition TGM depends on the rate of formation above the surface of the material of volatile components in a concentration greater than the lower CPRP. The process of formation of volatile components comes with energy costs and for materials of different composition begins at different temperatures and proceeds with different intensity. The ability of a material to resist heat without changing the chemical structure is called thermal resistance of the material.

Flame spread over TGM surface

After ignition of the TGM, the flame front moves along the surface. The spread of combustion occurs due to the transfer of heat from the combustion zone to the still non-burning areas of the material. Heat transfer is due to radiation, convection and thermal conductivity. Depending on the combustion conditions, the ratio of the quantities of heat supplied by these types of heat transfer may be different. Therefore, the speed of flame propagation over the surface of the TGM depends on the burning conditions.

The greatest influence on the speed of flame propagation over the surface of TGM is exerted by the following factors:

- the nature of the material, its physical and chemical properties (the rate of formation of volatile products);

- material moisture;

- sample orientation in space;

- air flow speed and direction;

- the initial temperature of the material;

- geometrical dimensions of the sample (thickness, dispersion).

Burning cellulosic materials

Cellulose ?? It is a high molecular weight polysaccharide composed of glucose molecules.

Consider the behavior when heating wood as the most common combustible material.

The burning of wood is significantly different from the burning of liquids and gases, and can proceed simultaneously in several modes - homogeneous and heterogeneous. Therefore, during the combustion of wood, two phases can be distinguished: 1) homogeneous (ie, fiery) combustion of gaseous decomposition products and 2) heterogeneous combustion of the resulting solid carbon residue.

The stage of fiery burning takes a shorter period of time, but it releases about 55–60% of all energy. The rate of heterogeneous combustion is determined by the rate at which air reaches the surface.

Smoldering

Smoldering ?? flameless burning of fibrous and porous materials that form a solid carbon residue when heated. This is a special combustion mode, when the combustible gases formed as a result of pyrolysis do not burn, but only a heterogeneous combustion of the carbon residue (surface oxidation) occurs. Decay occurs due to the oxygen contained in the pores of the material.

Materials that can smolder include a wide range of materials of plant origin (paper, cellulose fabrics, sawdust), latex rubber, some types of plastics (polyurethane foam, foam films). Materials that can melt or decompose to produce little carbon residue are not capable of smoldering.

Burning dust

Dust ?? a colloid system consisting of a solid dispersed phase and a gaseous dispersion medium, i.e. is a solid dispersed (finely ground) in a gaseous medium.

The dispersed phase may consist of particles of the same size ( monodisperse system) or particles of different size ( polydisperse system). All industrial dust polydisperse.

Depending on the average particle size, the dust can stay in suspension for a long time or immediately settle after a short transition to suspension.

The dispersed system, which is a dust suspended in the air, is called by aerosol. The settled dust is called airgel.

Even in the settled state, each individual particle of the crushed substance is surrounded on all sides by a gas (air) envelope.

By their properties, aerosols occupy an intermediate position between the airgel and the homogeneous gas-air mixture. As well as aerogels are heterogeneous dispersed systems with the same solid phase, and their behavior is determined by the physicochemical properties of this solid phase. With air-gas mixtures, aerosols are similar in that the combustion of most of them occurs with an explosion, and they are characterized by many parameters typical of gas mixtures.

Of the properties of dust that determine their fire hazard, the most important are: dispersion, chemical activity, adsorption capacity, tendency to electrification.

Features of burning airgel

The main parameters characterizing the fire hazard of an airgel are the ignition temperature and auto-ignition.

In general, the burning of dust in the settled state is in many ways reminiscent of the burning of solid combustible material from which this dust is obtained. A distinctive feature of the airgel is its ability to move into a suspended state. When heated, all the preparatory processes characteristic of solid combustible materials flow, however, their flow rate is higher, which is explained by the developed surface, increased chemical activity, reduced thermal conductivity of the material as a result of grinding, increased dust adsorption capacity. This causes a shorter period of induction of ignition, a higher rate of propagation of combustion, as well as an increased tendency to spontaneous combustion as compared to the starting material from which dust was obtained.

Oxidation processes occur simultaneously both on the surface of the dust layer and in its depth. In this case, the reaction involves oxygen adsorbed on the surface of the material. The rate of oxidation under the layer of combustible dust is an order of magnitude lower than on the surface, as a result burning in the depth of dust deposits can go into a smoldering mode. Smoldering dust is a great danger, because 1) the released combustible decomposition products can accumulate in closed volumes, and combustion from diffusion can turn into kinetic; 2) even with a weak shaking (turbulence), the smoldering mass may self-ignite due to a sharp influx of oxygen and cause an explosion of vortex dust.

Peculiarities of aerosol burning

Aerosols are flammable and burn like gas-air mixtures. Therefore, their fire danger is characterized by the same parameters as gas-air mixtures: KPP, minimum ignition energy, maximum explosion pressure.

The propensity of aerosols to coagulation (adhesion) and deposition significantly distinguishes them from gas-air mixtures. This property causes higher ignition energy (two orders of magnitude higher) than for gas mixtures.

If flame propagation in gas mixtures is caused by heating of the cold mixture due to thermal conductivity, then flame propagation in dusty air mixtures occurs due to heating the cold mixture by radiationemitted by the front of the flame.

Inflammation and propagation of a flame in an aerosol occurs only if the concentration is in the range of concentration limits of ignition.

The lowest concentration of dust in the air at which the mixture is able to ignite from the ignition source with the subsequent spread of combustion to the entire volume of the mixture is called lower concentration limit of flame propagation.

The upper concentration limit of flame propagation for dust also exists and can be determined under laboratory conditions, but is not used in practice. This is due to the fact that the constant existence of aerosol concentrations above the upper limit, when ignition is excluded, is impossible and there will always be such a moment when, as a result of precipitation, the concentration of dust will be in an explosive range.

In the aerosol state, dust can ignite and burn in the kinetic mode, i.e. with an explosion, therefore, the NKPRP is taken as the main parameter of fire danger. In the settled state, dust can spontaneously ignite and spontaneously ignite; therefore, the self-ignition temperature T St is used to assess the fire hazard properties of an airgel.

All combustible dust can be divided into two groups and four classes:

The first group ?? explosive dust. Dust capable of kinetic combustion and having a lower concentration limit of flame propagation up to 65 grams per cubic meter, inclusive.

1 class ?? the most explosive dust with NKPRP 15 g / m and below;

2 class ?? explosive dust with NKPRP from 15 to 65 g / m;

The second group ?? flammable dust

3 class ?? the most flammable dust with T St not higher than 250 ° C;

4th grade ?? flammable dust with a T st above 250 ° C.

NKPRP dusty systems depends on a number of factors, the main of which are:

- power from;

- dust moisture;

- ash content of the material;

- the content of volatile components;

- non-combustible gas content;

- dust dispersion.

The scientific theory of combustion was first developed by M.V. Lomonosov in 1756. Currently, the generally accepted theories of combustion are the peroxide oxidation theory of Academician A.N. Bach, developed by him in 1897, and the chain theory of Academician N.N. Semenova, developed in 1927

According to the peroxide theory of oxidation, peroxide of this substance is formed as a result of the interaction of the oxidizable substance with oxygen. In the reaction enter the excited oxygen molecules, whose energy is higher than the average energy of the molecules of a substance. This energy

A.N. Bach called the activation energy. Under the action of this energy, the oxygen molecules go into an active state, which is considered as breaking one of the two bonds in the oxygen molecule.

Molecules can be activated by different types of energy. Thus, the activation of the chlorine molecule occurs under the action of light energy, and the oxygen molecule - under the action of thermal energy. The group -O-O-, in which the atoms are bound weaker than in the free molecule, combining with the oxidizable substance, forms a peroxide - a strong oxidizing agent.

The chain theory of oxidation develops and complements the peroxide and allows to explain the kinetic side of the phenomenon and the causes of the acceleration of the process, and the ways of activation of the reacting substances.

It is known, for example, that a mixture of hydrogen and chlorine, cooked in the dark, explodes in the light. The primary reaction of the chain

is the decomposition of the chlorine molecule into atoms by absorbing a quantum of light. The chlorine atom reacts with a hydrogen molecule to form a hydrogen atom and an HCl molecule. The hydrogen atom formed during the reaction reacts with the chlorine molecule, regenerating the chlorine atom.

Consequently, the formation of a single chlorine atom causes a chain of reactions that stop when, as a result of recombination or reaction with an impurity, the active center is eliminated - a hydrogen or chlorine atom.

Combustion is a chemical oxidation reaction, accompanied by the release of large amounts of heat and usually luminescence.

Fire - uncontrolled burning, occurring outside a special focus and causing material damage.

Usually burning takes place in the air, and oxygen acts as an oxidizing agent. However, there are a number of substances that can burn, combining with other oxidants. For example, acetylene burns in chlorine, magnesium in carbon dioxide, phosphorus ignites, reacting with chlorine and bromine, etc. Acetylene, chloride nitrogen and a number of other gases can explode during compression, resulting in the decomposition of the substance with the release of light and heat. Thus, the combustion process can occur not only during the chemical reaction of the compound, but also during the decomposition reaction.

Chemical combustion processes are usually accompanied by physical processes of the transition of a combustible substance into a liquid and gaseous state. For example, wax, paraffin and some other substances under the action of heat are first converted into a liquid, and then into steam, which burns with a flame outside the combustible substance. Flammable and combustible liquids themselves do not burn, but their vapors that form on the surface under the influence of heat are burning.

To burn a combustible substance in air, it is necessary to have oxygen (at least 14–15% by volume of air) or another oxidizing agent and the temperature at which it can burn. Combustion can occur not only due to the oxygen of the air, but also due to the oxygen contained in the composition of other

substances and easily released from them (peroxides, chlorates, nitrate, etc.).

The burning process proceeds more intensively, the greater the specific area of contact of the combustible substance with the oxidizer (the paper cuts burn more intensely than the paper bundles) and the higher the concentration of the oxidizer, temperature and pressure. If you eliminate at least one of the causes of combustion, the process stops.

During fires, the temperature reaches 1000-1300С, and in some cases, for example, when burning magnesium alloys, - 3000С.

Explosion, detonation, flash, fire, spontaneous combustion, ignition, self-ignition are all types of combustion.

Explosion - extremely rapid chemical transformation, accompanied by the release of energy and the formation of compressed gases capable of performing mechanical work. This work is done as a result of the appearance of a shock wave — a sudden change in pressure propagating in a medium with a supersonic velocity.

The propagation of an explosion, due to the passage of a shock wave through a substance and flowing to a given substance under given conditions with a constant supersonic speed (of the order of thousands of meters per second), is called detonation.

Explosive mixtures of combustible gases and vapors (at a certain concentration in the air) - gasoline, toluene, ethyl alcohol, acetone, ethyl acetate, etc. - can be produced in production shops of in-depth and flexographic printing, paint departments, production departments of photopolymer forms, and charging. batteries. This can occur in the absence of an effective ventilation system, violation of technology, inconsistency of electrical installations with the requirements of the EMP, etc. Explosive mixtures with air are also formed by suspended dust of starch, paper, aluminum, magnesium, rosin, shellac, etc. The most dangerous is dust, which forms explosive mixtures with

air at concentrations up to 15 (aluminum, rosin, shellac, etc.).

Flash - rapid combustion of the combustible mixture, not accompanied by the formation of compressed gases. In this case, not enough heat is released to form a new concentration of vapors of the combustible mixture, and the burning stops.

Fire- the occurrence of combustion under the action of the ignition source.

Spontaneous combustion - the phenomenon of a sharp increase in the rate of exothermic reactions, leading to the occurrence of a burning substance (material, mixture) in the absence of an ignition source. Spontaneous combustion can be thermal, microbiological and chemical.

Thermal spontaneous combustion occurs when an external heating of a substance (material, mixture) exceeds its temperature of ignition, i.e. the lowest temperature at which its self-heating occurs. For example, oak, pine, spruce wood and products made from it at an ambient temperature of more than 100 ° C begin to self-heat - its unstable compounds decompose. At 230-270C decomposition is accelerated, and oxidation begins. The process of decomposition of wood is exothermic, and if the heat released during oxidation exceeds the heat transfer to the environment, the accumulation of heat leads to spontaneous combustion.

To prevent thermal spontaneous combustion, it is necessary to protect combustible substances and materials from the action of external heat sources.

Microbiological spontaneous combustion occurs as a result of self-heating, which occurs under the influence of the vital activity of microorganisms in the mass of a substance (material, mixture). For microbiological spontaneous combustion tend substances of plant origin (mostly not dried) - hay, straw, sawdust, leaves, wet loose peat, etc.

Chemical spontaneous combustion occurs as a result of chemical interaction of substances. For example, some brown and black coal, piled into piles, can, due to oxidation and adsorption, self-heat and, if there is insufficient heat transfer to the environment, it can ignite spontaneously. If you moisten fibrous or crushed materials (for example, cotton wool, rags, wood or even metal sawdust) with vegetable oils or animal fats, they are distributed in a thin layer over the large surface of these materials, and then intensively oxidized and polymerized, which is accompanied by significant heat generation. Oiled fibrous material, folded in a pile, has a low heat transfer to the environment. Therefore, the accumulated heat helps to accelerate the process of oxidation and polymerization, as well as further increase in temperature. As soon as the temperature of the oiled material reaches the ignition temperature of the oil, it will self-ignite.

Mineral oils (refined petroleum products) are not prone to spontaneous combustion.

Ignition - This is a fire, accompanied by the appearance of a flame.

Self ignition - spontaneous combustion, accompanied by the appearance of a flame.

In the practice of industrial enterprises, cases of spontaneous combustion of oiled cleaning materials and overalls stacked in a pile are known; lederin, the top layer of which contains flaxseed oil.

Some chemicals may ignite spontaneously or cause other substances to ignite in the air, when exposed to water and when mixed with each other.

As a result of the oxidation reaction, especially in the presence of moisture, certain metallic powders (aluminum and zinc) ignite

therefore, they must be stored in hermetically sealed containers.

Calcium and alkali metal carbides, hydrides of alkali and alkaline earth metals, etc., are substances that cause combustion under the action of water on them. These substances, when interacting with water, usually emit flammable gases, which, when heated by the heat of reaction, self-ignite.

Chlorine and other halides, nitric acid, chromic anhydride, bleach, peroxide of sodium and potassium, etc. can be substances that ignite spontaneously when mixed with each other. Some of these oxidants can cause spontaneous combustion when mixed with or in contact with organic substances . Others ignite spontaneously when exposed to a mixture of an oxidizing agent with a flammable substance, sulfuric or nitric acid, upon impact or heat.

Substances self-igniting in air include phosphorus, zinc and aluminum dust, sulfides, carbides of alkali metals, etc.

Propensity to self-ignition of substances and materials into account when developing measures for fire prevention during their storage, transportation, drying, performing technological operations, etc.

The list of indicators required to assess the fire and explosion hazard and fire hazard of substances and materials, depending on their state of aggregation, is given in Table. 1 of the annex to the Federal Law "Technical Regulations on Fire Safety Requirements. Federal Law of the Russian Federation 123 ".

The main indicators in assessing the fire hazard of liquids are: a flammability group; flash point; flash point and concentration limits of ignition. The main indicators in assessing the fire hazard of solids and materials are the flammability group; ignition temperature, autoignition temperature, tendency to spontaneous combustion.

Flammability group. Substances and materials are divided by flammability into three groups: incombustible, i.e. incapable of burning in air of ordinary composition; slow-burning, which can ignite and burn in the presence of a source of ignition, but are not able to burn themselves when it is removed; combustible, igniting from the ignition source and continuing to burn when it is removed. Combustible materials are subdivided, in turn, into flammable, i.e. those that ignite from an ignition source of minor energy (a match, a spark, etc.) without preheating, and are hard to ignite, which ignite only from a relatively powerful ignition source.

The flash point is the lowest (under the conditions of special tests) temperature of a combustible substance, at which vapors and gases are formed above its surface, capable of flashing in the air from the ignition source, but the rate of their formation is still insufficient for subsequent burning.

The term “flash point” usually refers to flammable liquids, but some solids (camphor, naphthalene, phosphorus, etc.) that evaporate at normal temperature are also characterized by a flash point. The lower the flash point of a flammable liquid, the more dangerous it is in terms of fire.

According to Ormandy and Graven's rule, the flash point is

t in = t kip. Xk

where is the boiling point, hail. TO; K is a coefficient equal to 0.736.

According to fire hazard, depending on the flash point, flammable liquids are divided into two classes:

Grade 1 - flammable liquids (flammable liquids) - gasoline, toluene, benzene, acetone, methyl and ethyl alcohols, ether, kerosene, turpentine, etc .;

2nd class - flammable liquids (GJ) - mineral oils, fuel oils, formalin, etc .;

The ignition temperature is the temperature of a combustible substance at which it emits combustible vapors and gases at such a rate that after ignition from a source of ignition, a steady burning occurs.

Auto-ignition temperature is the lowest temperature of a substance (material, mixture), at which the rate of exothermic reactions sharply increases, resulting in burning with the formation of a flame.

Auto-ignition temperature is not constant even for the same substance. It depends on the concentration of oxygen in the air, pressure, heat transfer conditions to the environment, etc. For example, the auto-ignition temperature of combustible gases and vapors ranges from 300-700С, wood, peat, paper, cardboard - 250-400С, celluloid - 140-180С, vinyl plastic - 580С, rubber - 400С.

The concentration limits of ignition are the minimum and maximum concentrations of the ignition region, i.e. concentration areas of a combustible substance, within which its mixtures with a given oxidizing agent (usually air) are able to ignite from the ignition source with the subsequent spread of combustion through the mixture, arbitrarily far from the ignition source. For example, for acetone, the lower concentration limit of ignition (explosion) is 2.6%, and the top is 12.2% (volume), for gasoline A-76, respectively, 0.76% and 5.03%, for ethyl alcohol - 3, 3% and 18.4%, natural gas 5% and 16%, etc.

The greater the lower concentration limit of ignition and the wider the gap between the lower and upper limit of ignition, the greater the explosion hazard of combustible gases, vapors and dust. Thus, the explosion hazard is directly proportional to the size of the ignition area.

Fires are classified according to the type of combustible material and are divided into the following classes.

Fires of solid combustible substances and materials (A).

Fires of flammable liquids or meltable solids and

materials (B).

Fires of gases (C).

Fires of metals (D).

Fires of combustible substances and materials of electrical installations that are under voltage (E).

Fires of nuclear materials, radioactive waste and radioactive substances (F).

A significant factor hindering the introduction of various polymeric materials is their fire hazard due to combustibility and accompanying processes.

Combustibility- it is a complex characteristic of a material or structure - determines the ability of a material to ignite, maintain and distribute the combustion process. It is characterized by the following values - the temperature of ignition or spontaneous ignition, burning rate and flame spread over the surface, as well as the conditions under which the combustion process is possible (atmospheric composition, oxygen index, temperature index). |

|  |

Flammability- This is a fiery burning substance initiated by the ignition source and continuing after its removal. To assess the fire hazard of a substance determine the ignition temperature. Among thermoplastics, the highest rates for CPVC are 482 ° C, and also for polypropylene 325 ° C.

Oxygen indexshowing the percentage of oxygen needed to maintain a burning substance. The oxygen content in the atmosphere is 21%, and the oxygen index CPVC 60 - that is, the burning of this material can occur with an additional supply of 39% oxygen. Therefore, this material is referred to as "self-extinguishing." This distinguishes this material favorably from other thermoplastics, such as polypropylene and polyethylene, whose oxygen index is 17 and therefore its combustion continues after ignition. In such cases, the formation of burning drops, which serve as an additional source of ignition, is a great danger. In the case of CPVC, the material does not melt and hot drops are not formed.

Toxicity. The toxicity of substances formed during combustion is an undesirable factor for human safety. It is smaller, the lower the percentage of smoke and the main products of combustion - CO and CO2.

Associated combustion processes:

- the emission of smoke during combustion and exposure to flame,

- toxicity of products of combustion and pyrolysis - decomposition of the substance under the action of high temperatures,

- fire resistance of a material or product - the ability to maintain physical and mechanical characteristics (strength, stiffness) and functional properties when exposed to a flame.

Therefore, reducing the flammability of polymeric materials is the task of optimizing the complex characteristics of the material being created.

The nature of most polymeric materials is such that they cannot be made completely fireproof. The only thing that can be done is to reduce their ability to burn and maintain burning. For this purpose, additives are used that impede ignition and reduce the rate of flame propagation - flame retardants.

Fig. № 1. Scheme of the combustion process Fig. № 1. Scheme of the combustion process

|

Combustion of polymers is a very complex physico-chemical process (Scheme 1), which includes chemical reactions during polymer degradation, as well as chemical reactions for the conversion and oxidation of gaseous products, with intensive heat release and mass carryover. As a result of chemical reactions, two types of combustion product are formed - combustible and non-combustible gases and ash (carbon-containing or mineral). Table 1 shows the ignition temperature of polymers and their decomposition products in the combustion process.

Table number 1 .

|

Material |

Pyrolysis products |

Combustion products |

Ignition temperature, ° С |

Oxygen index,% |

|

Polyolefins |

olefins, paraffins, alicyclic hydrocarbon residues |

CO, CO² |

17,4 |

|

|

Polystyrene |

monomers, dimers, trimers of styrene |

CO, CO² |

18,6 |

|

|

Polyacrylates |

acrylic monomers |

CO, CO² |

17,3 |

|

|

PVC |

aromatic hydrocarbons, HCl |

CO, CO², HCl |

47 (self-extinguishing) |

|

|

Polycarbonate |

CO², phenol |

CO, CO² |

||

|

Polyamide - 6,6 |

amines, CO, CO² |

CO, CO², NH³, amines |

28.7 (self-extinguishing) |

|

|

Polyethers |

styrene, benzoic acid |

CO, CO² |

22,8 |

During the combustion of organic polymeric materials, the oxidizing agent is air oxygen, and hydrogen and carbon-containing gaseous products of destruction of the polymer are combustible. When heated, the macromolecules easily decompose into low molecular weight saturated and unsaturated hydrocarbons, which undergo exothermic oxidation reactions, that is, the reaction is accompanied by the release of heat.

During the burning of polymers, there are also observed critical phenomena characteristic of combustion processes in general. Reducing the flame temperature for one reason or another leads to a jump-like transition from one oxidation mode — combustion — to another, to very slow oxidation. These modes differ in speed by many orders of magnitude. Therefore, we can talk about the existence of critical conditions that define the boundaries of the possible burning of this material. It should be noted that these conditions depend on the geometry of the samples and the flame, the temperature of the polymer and the gaseous medium, and are not absolute characteristics of this material.

One of the most characteristic examples of the practical use of critical phenomena in the combustion of polymers is an experimental method for assessing their flammability, first proposed by the British scientist Martin.

| The sample is set on fire from above with a special gas burner, after which the burner is removed, and the sample either continues to burn on its own, burning almost to the end, or quickly decays. Such experiments are carried out with a different composition of the gas atmosphere, that is, a different ratio of oxygen and nitrogen. The critical oxygen concentration in the mixture (in vol.%), Above which independent combustion is possible, and not lower, is called the oxygen index (CI) and characterizes the flammability of this material. The physical essence of the method is that as the oxygen concentration decreases, the heat consumption for heating of the inert gas, nitrogen, increases, the flame temperature decreases, which determines the critical conditions of combustion. Currently this method is widely used throughout the world. |

Table number 2 .

Classification of the degree of flammability of materials according to the method of Martin

|

Indicator |

V - 2 |

V - 1 |

V - 0 |

|||

|

Ignition quantity |

||||||

|

Burning time after flame removal, s |

||||||

|

The total burning time of five samples, two ignitions, sec, |

||||||

|

The presence of droplets, flammable cotton wool |

yes |

not |

not |

not |

not |

|

|

Maximum time of decay of the sample, s |

||||||

|

Burning the sample before clamping |

not |

not |

not |

not |

not |

At the moment, the process of transition of the EEC to a single standard of materials for construction, adopted in 2001, is nearing completion. In this standard, the flammability is determined by the letters of the alphabet: A ( slow-burning), E ( short-term fire resistance) and F ( non-combustible materials).

Flame retardants are divided into 3 large groups.:

Supplements of the first type

used mainly for reactoplast (epoxy, unsaturated polyester and the like resins). Dibromoneopentyl glycol (DBNPG) is mainly used for polyester resins, and organic phosphorus compounds are recognized as the best system for epoxy resin. These compounds are embedded in the chemical network of thermoset plastics and do not impair the physical and mechanical properties of the products.

Supplements of the second type

the burning of the polymer is stopped at an early stage, that is, at the stage of its thermal decomposition, accompanied by the release of combustible gaseous products.

The intumescent process consists of a combination of coke formation and foaming of the surface of the burning polymer. The resulting foamed cellular coke layer, the density of which decreases with increasing temperature, protects the burning material from the effects of heat flow or flame.

Type 3 supplements

used for thermoplastics, thermosets and elastomers.

There are several types of such additives, of which three are most common:

halogenated;

phosphorus-containing;

metal hydroxides.

The effectiveness of halogen-containing flame retardants increases in the F-Cl-Br-I series. Most often, chlorine and bromine containing compounds are used as flame retardants, as they provide the best price / quality ratio.

Bromine containing flame retardants, are much more effective than chlorine-containing ones, since their combustion products are less volatile. In addition, chlorine-containing flame retardants emit chlorine in a wide temperature range, therefore its content in the gas phase is low, and bromine-containing flame retardants decompose in a narrow temperature range, thus providing the optimum concentration of bromine in the gas phase. Flame retardants with bromine compounds are easily recycled due to the high level of heat resistance.

Chlorine-containing flame retardants: contain a large amount of chlorine and act in the gas phase. Most often used in combination with antimony oxides as a synergist. They are relatively cheap, do not decompose under the action of light, but to achieve the desired class of fire safety requires a large percentage of input into the polymer. They are less thermostable compared to bromine-containing fire retardants, but tend to cause severe corrosion of equipment.

Phosphorus-containing flame retardants. Phosphorus-containing compounds can be organic and inorganic. They are active in the gas or condensed phase, and sometimes in both.

The range of phosphorus-containing compounds is quite wide, and for a start, you can divide them into 2 groups - halogen-containing and halogen-free.

The advantage of compounds containing halogen and phosphorus is that, firstly, by cleaving the halogen radicals during decomposition, the radicals are deactivated by the usual halogen-free mechanism of the radicals H * and OH * and, secondly, they promote the formation of carbonized structures ( soot, ash).

Synergistic blends. Most of the halogen-containing flame retardants are used in the form of synergistic mixtures with antimony oxides. Antimony oxide itself does not delay burning, as it melts at temperatures above the ignition temperatures of most plastics. However, mixed with halogen-containing compounds, antimony oxide forms halides and hydroxy halides of antimony, which are in a gaseous state at the ignition temperature and dilute combustible gases. In addition, the halides and hydroxy halides act as OH * radical scavengers similar to the action of HCl and HBr. Antimony oxides are often used to increase the fire resistance of PVC, due to the synergistic effect with chlorine contained in the starting polymer. It is not recommended to use antimony oxides in transparent and translucent products. In this case, and for the manufacture of products with improved electrical insulating properties, iron oxide can be used as a synergist. Comprehensive studies have shown that antimony oxide is not a carcinogenic compound.

Criteria for the selection of halogen-containing flame retardant.

When choosing a flame retardant, the main factors are: type of polymer, requirements for flammability and its behavior during polymer processing - its heat resistance, melting point and quality of dispersion in the polymer.

Efficiency of flame retardants does not depend on the degree of their dispersion or solubility in the polymer, since most of the reactions associated with the inhibition of combustion occur in the gas phase. It is determined by the diffusion rate of halogen radicals and the rate of their interaction with free radicals.

But it is necessary to take into account the effect of the flame retardant on the physico-mechanical, electrical and other properties determined by the end use of the product. The introduction of flame retardants usually leads to a certain decrease in the physicomechanical, dielectric and other operational and technological properties of materials.

This is where the important factor of uniform dispersion is. Moreover, it is recommended to choose a flame retardant so that halogen radicals are formed at the same temperature as the combustible products of the pyrolysis of the polymer. Thus, free radical scavengers will be in the gas phase simultaneously with the fuel, which will ensure maximum efficiency of the flame retardant action. The rate of formation of halogen radicals should be such that the capture of active radicals can occur during the entire time that the surface temperature remains above the ignition temperature of the volatiles.

Other flame retardants .

Metal hydroxides .

Aluminum and magnesium hydroxides occupy the first place among the flame retardants in terms of use (more than 40% of the total volume of flame retardants). This is due to their low cost compared to halogen or phosphorus based systems.

Mechanism of action. Metal hydroxides under the influence of high temperatures decompose with the release of water. The decomposition reaction is endothermic (accompanied by heat absorption), which leads to the cooling of the substrate to temperatures below the flash point. The formation of water contributes to the dilution of flammable gases released during decomposition, weakens the effect of oxygen and reduces the rate of combustion. The effectiveness of hydroxides is directly proportional to their content in the polymer.

| Magnesium Hydroxide (MH) - is a white powder with a particle size of from 0.5 to 5 microns. To achieve the appropriate flame retardant effect is introduced in the amount of 50-70% by weight of the polymer. Magnesium hydroxide is more expensive than aluminum hydroxide, so the volume of use is much less. But it has one indisputable advantage - it has a higher heat resistance (up to 3000 0 С), therefore it can be used in the processing of structural thermoplastics. It is mainly used in polypropylene, ABS plastic and polyphenylidene oxide. It is not recommended to use this fire retardant in thermoplastic polyesters (PET, PBT), as it accelerates the degradation of such polymers. The pictures show a micrograph of a particle of magnesium hydroxide and a polymer foam coke with magnesium hydroxide. |

Aluminum hydroxide (ATH)

- it is used in elastomers, thermo-plastics and thermoplastics. It decomposes at temperatures of 190 - 2300С depending on the particle size (0.25-3 microns). One of the main areas of application is to increase the fire resistance of styrene-butadiene latex used in the manufacture of carpet coverings. It is also widely used for the manufacture of non-combustible elastomers for cable insulation, conveyor belts, roofing materials and hoses. Can be used to improve the fire resistance of unsaturated polyesters. This fire retardant is widely used in polyolefins, PVC, thermoplastic elastomers. |

Melamine and its derivatives - a small but fairly rapidly developing market segment.

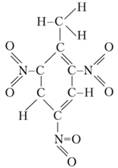

|  |  |

It includes melamine, its homologs and salts with organic and inorganic acids (boric, cyanuric and phosphoric). The main producer of additives of this type is DSM. When using melamine containing flame retardants, endothermic decomposition occurs with dilution of gases, absorption of active radicals with the formation of carbon structures. Moreover, melamine containing compounds are inexpensive, non-toxic and do not cause equipment corrosion.

Currently, this class of fire retardants is used mainly in foamed and thermoplastic polyurethanes, polyamides. Melamine-containing flame retardants for polyolefins and thermoplastic polyesters are also being developed.

Nanocompositeshave many advantages over traditional flame retardants. Small amounts of modified layered silicates are used as fillers. Thus, their mechanical properties are the same as those of unfilled polymers. The processing of nanocomposites is very simple, while nanocomposites do not contain halogens and are considered as an environmentally friendly alternative.

The mechanism of flame suppression through the introduction of silicate nanocomposites is based on the formation of a carbon layer and its structure. The carbonaceous layer isolates the base polymer from the heat source and thus forms a barrier that reduces the release of volatile products during the combustion process. Although flame suppression is a relatively new field of application for nanocomposites, they are very important as fillers for creating relatively flame resistant polymers with improved properties. Combinations of organic alumina with other flame retardant fillers, such as aluminum hydroxide, also show promising properties.

It is usually used in combination with phosphorus-containing compounds, antimony oxides or metal hydroxides, which create a substrate for a layer of expanded graphite. The disadvantage of graphite is black color and electrical conductivity, which limits its use.

Trends in the flame retardant market.

The global market for flame retardants is estimated at about 30% of the total consumption of additives in polymers (with the exception of pigments and dyes). The structure of the fire retardant market is as follows:

Indicators of fire hazard substances.Certain indicators are necessary for a complete assessment of the fire hazard of solids and materials, as well as liquids and gases.

Indicators of fire hazard substances.Certain indicators are necessary for a complete assessment of the fire hazard of solids and materials, as well as liquids and gases.

Ignition temperatureis called the lowest temperature of a combustible substance, at which it emits combustible vapors or gases at such a rate that after ignition from an external source of ignition, the substance burns steadily. The ignition temperature is an indicator of fire danger only of combustible substances and materials, since it characterizes their ability to burn independently.

Auto-ignition temperature called the lowest temperature of a substance (or its mixture with air), at which there is a sharp increase in the rate of exothermic reactions, leading to the occurrence of fiery burning.

The ignition temperature of gases and vapors is taken into account in the following cases:

the classification of gases and vapors of flammable liquids by explosion groups for choosing the type of electrical equipment (with reference to the standard auto-ignition temperature);

the choice of temperature conditions for the safe use of a substance when it is heated to high temperatures (in this case, the minimum auto-ignition temperature is used);

calculating the maximum allowable heating temperature for non-insulated surfaces of process, electrical and other equipment;

investigate the cause of the fire, if it is necessary to determine whether a substance could ignite from a heated surface.

Propensity to spontaneous combustioncharacterizes the ability of a number of substances and materials to ignite spontaneously when heated to relatively low temperatures or contact with other substances, as well as when exposed to heat generated by microorganisms in the process of their vital activity. In accordance with this, thermal, chemical and microbiological spontaneous combustion are distinguished.

Tendency to thermal spontaneous combustion characterized by temperatures of self-heating and smoldering, as well as the dependence of the temperature of the medium at which spontaneous combustion is observed, on the size and shape of the sample. The propensity to spontaneous combustion into account when developing fire prevention measures.

Self-heating temperature is the lowest temperature at which practically distinguishable exothermic oxidation and decomposition processes occur in a substance or material, which can lead to spontaneous combustion.

Heating to a self-heating temperature, the lowest temperature of a substance, can potentially pose a fire hazard. The temperature of self-heating is taken into account when determining the conditions for safe long-term (or constant) heating of the substance.

Safe heating temperature this substance or material (regardless of sample size) should be considered a temperature not exceeding 90% of the value of the self-heating temperature.

Smoldering temperatureis called the critical temperature of a solid at which the rate of the self-heating process increases dramatically, which leads to the appearance of a smoldering hearth. The temperature of smoldering is taken into account when investigating the causes of fires, determining the safe conditions for heating solid materials, etc.

Consider the features of the oxidation process of self-igniting substances of plant origin, fossil coal, oil and grease, chemicals and mixtures.

Among the self-igniting substances of plant origin include meal, fish meal, hay, oil cakes, etc. Wet plant products, which continue the activity of microorganisms, are particularly susceptible to spontaneous combustion.

The presence of moisture in plant products at certain temperatures is accompanied by the multiplication of microorganisms, the intensification of their vital activity which causes an increase in temperature. Plant foods are poor conductors of heat, so they further increase the temperature.

Under conditions favorable for heat accumulation: a considerable mass of plant product, for example, hay or oil cake in the hold, the temperature can reach 70 ° C.

At this temperature, microorganisms die, and their decomposition is accompanied by a further increase in temperature with the formation of porous coal, which is able to absorb vapors and gases in a large volume.

This process is also accompanied by the release of heat and a gradual increase in temperature to 100-130 ° C, at which the decomposition of new compounds occurs with the formation of porous coal. At a temperature of 200 ° C, cellulose, which is a part of plant products, decomposes, and a new type of coal is formed that can oxidize intensively. The process of oxidation of coal leads to a further increase in temperature, up to the occurrence of combustion.

Charcoal produced by thermal decomposition of cellulosic materials, such as charcoal, can also ignite spontaneously. And this happens immediately after its manufacture. Over time, its ability to absorb vapors and gases decreases, as a result of which charcoal, which has been in the air for a long time, loses its tendency to self-ignite.

Some types of fossil coal can oxidize at low temperatures and absorb oxygen from air and other gases or vapors. But the main cause of spontaneous combustion is the oxidation of coal. Coal absorption of vapor and gases is also accompanied by an increase in temperature.

Young coal containing moisture has the highest absorption capacity. So, freshly mined lignite contains 10 - 20% hygroscopic moisture, and lean - about 1%, so the latter is more resistant to spontaneous combustion. An increase in moisture causes an increase in the temperature of the coal to 60–75 ° C, and further heat is released due to the oxidation of the organic matter.

The development of the process of spontaneous combustion of fossil coal depends on the degree of its crushing: the finer the coal, the greater the surface absorption and oxidation, the greater their rate of flow, the more heat is released.

Often the cause of the fire is spontaneous combustion of fats and oils of mineral, vegetable or animal origin.with which fibrous materials and fabrics are impregnated.

Mineral oils (engine, diesel, transformer) are a mixture of saturated hydrocarbons and cannot ignite in pure form. Their spontaneous combustion is possible in the presence of impurities of vegetable oils. Vegetable oils (hemp, flaxseed, sunflower, cottonseed) and oils of animal origin (butter) are a mixture of glycerides of fatty acids.

Many chemicals and their mixtures are capable of self-heating when in contact with air or moisture. These processes often end in spontaneous combustion.

By their ability to self-ignite, chemicals are divided into three groups:

1st group.

Substances that ignite spontaneously in contact with air(activated carbon, white phosphorus, vegetable oils and fats, sulfur metals, aluminum powder, alkali metal carbide, powdered iron, zinc, etc.).

The oxidation of certain substances of this group, caused by their interaction with water vapor of air, is accompanied by the release of a large amount of heat and proceeds so quickly that it soon turns into combustion or explosion. For other substances, self-heating processes continue for a long time (for example, the process of auto-ignition of white phosphorus ends in burning after a few seconds, and the process of self-ignition of freshly prepared activated carbon lasts for several days).

2nd group.

Substances that cause combustion in the interaction of ha with water(alkali metals and their carbides, calcium oxide (quicklime), sodium peroxide, phosphorous calcium, phosphorous sodium, etc.).

The interaction of alkali metals with water or moisture of air is accompanied by the release of hydrogen, which ignites due to the heat of reaction. A small amount of water falling on quicklime causes self-heating, resulting in a strong warming up (before luminescence), so that combustible materials in the vicinity can ignite.

3rd group.

Substances that ignite spontaneously when mixed with one another. Thus, the effect of nitric acid on wood, paper, fabrics, turpentine and essential oils causes inflammation of the latter; Chromic anhydride ignites alcohols, esters and organic acids; acetylene, hydrogen, methane and ethylene ignite spontaneously in a chlorine atmosphere in daylight; the crushed iron (sawdust) ignites spontaneously in an atmosphere of chlorine; alkali metal carbides ignite under chlorine and carbon dioxide.

Flash point This is called the lowest temperature of a combustible substance at which, under conditions of special tests, vapors or gases are formed above its surface that can flash in air from an external source of ignition.

Flash point is a parameter that roughly indicates the temperature conditions under which a flammable substance becomes flammable. The flash point of flammable liquids in this classification is determined only in a closed crucible.

Ignition areagases (vapors) in air is the region of concentration of a given gas in air at atmospheric pressure, inside which mixtures of gas with air are able to ignite from an external source of ignition and then spread the flame through the mixture.

The boundary concentrations of the region of ignition are called respectively lower and upper flammability limits gases (vapors) in the air. The values of the limits of ignition are used in calculating the permissible concentrations of gases inside explosive process equipment, ventilation systems, as well as in determining the maximum permissible explosive concentration of vapors and gases when working with fire, a sparking instrument.

The concentration of gas or vapor in the air inside the process unit, not exceeding 50% of the lower limit of ignition, can be taken as explosion proof concentration. Explosion protection environment inside the equipment under normal process conditions does not give grounds to consider this equipment as non-explosive.

For the value of the maximum permissible explosion-proof concentration (PDVK) of vapors and gases when working with fire, a sparking tool should be taken concentration that does not exceed 5% of the lower limit of ignition of the vapor or gas in the air in the absence of the condensed phase in the apparatus in question.

Temperature limits of ignition of vapors in the airthese are the temperature limits of a substance at which saturated vapors form concentrations equal to the lower or upper concentration limit of ignition, respectively.

The temperature limits of ignition are taken into account when calculating safe temperature conditions in closed process volumes with liquids (fuel cargo tanks, etc.) operating at atmospheric pressure.

The temperature and maximum explosion pressure should be considered safe in relation to the possibility of formation of explosive vapor-air mixtures.

Maximum explosion pressure - This is the greatest pressure that occurs during an explosion. It is taken into account when calculating the explosion resistance of equipment with combustible gas, liquids and powdery substances, as well as safety valves and explosive membranes, shells of explosion-proof electrical equipment.

Flammability index (coefficient K) ~a dimensionless quantity that expresses the ratio of the amount of heat emitted by the sample during the test to the amount of heat emitted by the ignition source,

where q - heat released by the sample in the combustion process, kcal;

q and - thermal impulse, i.e. heat supplied to the sample from a permanent source

ignition, kcal.

According to the test results, the degree of inflammability is estimated as follows.

Fireproof materials- materials that, when heated to 750 ° C, do not burn and do not emit flammable gases in air in an amount sufficient to ignite them from the raised flame. Since the coefficient determined by the method of calorimetry TO< 0.1, such materials are not capable of burning in air.

Non-combustible materials- materials whose ignition temperature is lower than 750 ° C, and the material burns, smolders or is charred only under the influence of the flame brought up and stops burning or smoldering after its removal (0.1< TO< 0,5).

Flame-retardant materials (or self-extinguishing) - materials whose ignition temperature is lower than 750 ° C, and the material is burning, smoldering or charring under the influence of a raised flame. After its removal, the material continues to burn with a damped flame that does not propagate through the sample (0.5< TO< 2,1). Такие материалы не способны возгораться в воздушной среде даже при длительном воздействии источника зажигания незначительной энергии (пламени спички 750 - 800°С, тления папиросы 700 - 750°С и т.д.).

Combustible materials - materials whose ignition temperature is below 750 ° C, and the material, ignited from the flame brought, continues to burn or smolder after its removal (TO> 2,1).

Burning rate The burning rate of a solid depends on its form. Shredded solids in the form of sawdust or chips will burn faster than monolithic. In a crushed combustible material, a large burning surface is exposed to heat, therefore heat is absorbed much faster, evaporation occurs much more actively, with the release of a larger amount of vapors. Burning proceeds very intensively, as a result of which the combustible substance is consumed quickly. On the other hand, a monolithic combustible substance will burn longer than crushed.

Clouds of dust are made up of very small particles. When a cloud of flammable dust (eg, grain) mixes well with air and ignites, burning occurs very quickly and is often accompanied by an explosion. Such explosions were observed during the loading and unloading of grain and other crushed combustible substances.

There are two burning rates: mass and linear.

Mass burning rate is called the mass (t, kg) of the substance burned out per unit time (min, h).

Linear burning rate of solid combustible substancescalled the rate of propagation of fire (m / min) and the rate of growth of the area of the fire (m 2 / min). The burning rate of solids depends on the degree of grinding, humidity, bulk density, air access and a number of other factors.

The study of cases of fire on ships makes it possible to accept the following average linear burning rate (m / min) of various objects:

Management posts ................................................ ..................... 0.5

Living spaces................................................ ................... 1.0-1.2

Utility rooms, storage rooms for combustible materials ..... 0.6-1.0

Cargo space ..................................... ........... .............. 0.5-0.7

Car ferry decks ............... ............................... 1 ,five

The engine room with an internal combustion engine when burning diesel fuel under the stoves .... 10

Branch support mechanisms ......... ......................... 1,2

Electrical equipment rooms ........................................... 0.8

Boiler compartments when burning fuel oil under the stove ............. 8.0

Approximately during the first 2-3 minutes of a fire, the area of its focus quickly increases (on passenger ships, to 20 m 2 / min). This time usually takes to collect the alarm for the crew of the vessel and therefore there is no active fire fighting yet. In the next 10 minutes, when stationary means of water and foam extinguishing are used, the growth of the area of the fire center slows down.

The linear velocity of propagation of fire determines the area of the fire, and the degree of burning out of everything that can burn in this area is the duration of the fire.

Linear fluid burning ratecharacterized by the height of its layer (mm, cm), burnt per unit time (min, h). The speed of flame propagation during ignition of combustible gases is from 0.35 to 1.0 m / s.

Burnout ratecharacterized by the amount of fuel burning per unit time per unit area of combustion. It determines the intensity of combustion of materials during a fire. You need to know it to calculate the duration of the fire in any liquids. The burnout rate of the liquid spilled on the surface of seawater is about the same as when it burns out from the open surfaces of the containers.

Temperature. The most important parameter of ship fire, which largely determines not only engineering and preventive measures, but also tactical actions of emergency parties and groups of vessels is temperature. Of particular importance is the temperature during internal ship fires.

The intensity of heat transfer from the fire zone to the environment, the speed of gas flow, as well as the possibility of explosions that pose an extreme danger when extinguishing a fire depends on the temperature of the fire.

The temperature field of the fire is very heterogeneous.The closer to the fire zone, the temperature is usually higher. At the top of the room, the air is usually warmer than that of the decks. Taking into account the behavior of ship structures and materials and from a fire-tactical point of view, it is most convenient to take the average temperature of the flue gases filling the fire zone for the fire temperature. Also important are the temperatures on the surfaces of ship structures that enclose the fire zone: the temperature on the surface facing the fire, and the temperature on the surface opposite to the fire.

Approximately, the temperature at some points of the fire zone can be determined indirectly - by melting unburned materials that were in the fire zone, or by the incantation color of heated bodies (Table 4.1).

Table 4.1

Dependence of color of heat on temperature

When burning solid materialsthe temperature of the fire depends mainly on the type of materials, the magnitude of the fire load, the conditions of air flow and the removal of combustion products, as well as the duration of combustion.

The dependence of fire temperature on the duration of combustion for all solids has approximately the same character. Initially, the temperature rises sharply to a maximum, and as the material burns out, it gradually decreases. As the fire load increases, the total duration of burning increases, the maximum temperature of the fire increases, the temperature decreases more slowly, but the dependence character remains unchanged.

In conditions of limited gas exchange, for example, with closed openings in a residential area, the increase in temperature is much slower. The maximum temperature reaches 800-900 ° C.

Temperature conditions in the premises when burning liquids has its own characteristics. Since liquids are usually found in any vessels (in pallets, tanks, etc.), their combustion often has a local character. Under these conditions, if the ratio of the burning area to the deck area is close to unity, the temperature of the fire is approximately 1,100 ° C. If the burning area is only a small part of the deck area, the temperature is much lower.

The temperature of the fire while burning liquids and solid materials depends on what combustible materials prevail: if liquids make up only a small part of the fire load, then the temperature regime differs little from that of solid materials.

In case of internal fires in the zone of aggressive heat, there may be sudden convective flows of hot gases that occur when the conditions of gas exchange change, caused by the opening of doors and other openings.

The heat attack zone is part of the smoke area., it may be dangerous for a person's temperature. A person is able to be in a very short time in dry air, having a temperature of 80 - 100 ° C. Long stay at a temperature of 50 - 60 ° C causes the most serious consequences from overheating. Humid air at a temperature of 50 - 60 ° C for many people becomes intolerable in a few minutes.

When assessing the fire hazard of gases determine the area of ignition in air, the maximum explosion pressure, the self-ignition temperature, the category of explosive mixture, the minimum ignition energy, the minimum explosive oxygen content, the nominal rate of combustion.

When assessing the fire hazard of liquidsdetermine the flammability group, flash point, ignition temperature, ignition temperature limits, burnout rate. For flammable liquids, the area of ignition in air, the maximum explosion pressure, the category of an explosive mixture, the minimum ignition energy, the minimum explosive oxygen content, and the normal burning rate are additionally determined.

When assessing the fire hazard all solids and materials determine the flammability group, the ignition temperature. For solids with a melting point below 300 ° C, they additionally determine: flash point, temperature limits of vapor ignition in air.

For porous, fibrous and bulk materials, if necessary, they additionally determine the self-heating temperature, smoldering temperature during spontaneous combustion, temperature conditions of thermal self-ignition.

For substances powdered or capable of forming dust, the lower limit of the ignition of the aerospace suspension, the maximum explosion pressure of the aerospace, the minimum ignition energy of the aerospace, the minimum explosive oxygen content are additionally determined.

When assessing the fire hazard of a substance it is necessary to study its properties, to identify the possibility of their change over time and when used in certain conditions. In particular, it is important to take into account when the substance contacts with other active substances during prolonged heating, irradiation and other external influences, as a result of which its physicochemical properties may change.

When testing shipbuilding and other solid materials for flammability, a group of combustible materials is initially detected fire tube method.

Material considered to be flammable.if, when tested by the fire tube method, the time for self-burning or smoldering exceeds 1 min, and the weight loss of the sample is 20%. Combustible materials also include materials independently burning with a flame over the entire surface of the sample, regardless of the weight loss and time of its burning. Such materials are not subjected to further testing.

Materials having a weight loss of less than 20%, as well as materials losing 20% or more of weight, but burning or smoldering for less than 1 minute on their own for a final assessment of the degree of flammability are subjected to additional tests on calorimetry method.

Reception of indications of counters of hot and cold water supply

Reception of indications of counters of hot and cold water supply Calculation of the area of air ducts of various shapes and fittings

Calculation of the area of air ducts of various shapes and fittings Chemistry of combustion processes. Explosion energy

Chemistry of combustion processes. Explosion energy What will happen if you do not transmit meter readings

What will happen if you do not transmit meter readings